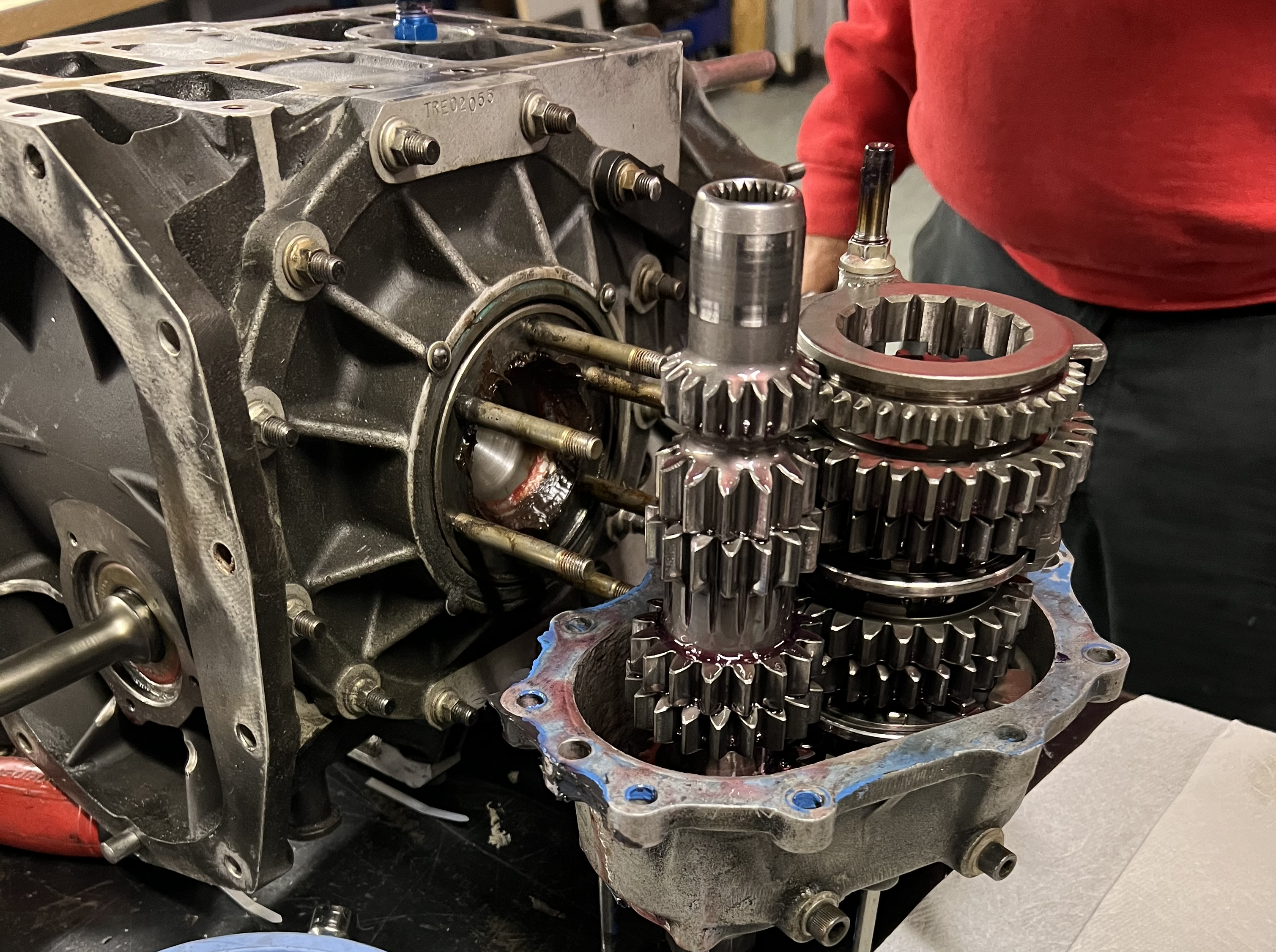

Gears produce quite a bit of heat and friction as they work against each other. This means that an oil is crucial to avoid abrasive damage between the gears, which will lead to the eventual degradation of a system.

Gear oils are one situation where using full synthetic oils is not always preferred. Mineral oils often perform better than synthetics at lower temperatures because they maintain a greater film strength by virtue of a higher pressure-viscosity coefficient. However, synthetic oils remain desirable in high temperature applications due to their increased ability to resist oxidation and thermal degradation. Additionally, synthetic oils can also handle a wider range of ambient temperatures while maintaining their viscosity.

Keep in mind dedicated gear oils tailored specifically for industrial processes contain a separate set of additives and protectant compounds than do Universal Automotive gear oils.

Viscosity and Gears

Generally, high viscosity oils are best for low speed, loaded gears with a rough surface. Higher viscosity provides a thicker film, higher wear resistance, and less deformation of the gears as time goes on.

Low viscosity oils, on the other hand, are best for high-speed systems with lower load bearing gears. They provide a thinner film and better cooling to match the higher speed of the gearbox in question.

Viscosity and Grades of Gear Oil

Like any other specialty oil, gear oils have their own grading system. For automotive purposes it is important to remember that you cannot just dump motor oil in the transmission. While motor oils are formulated for minimal interactions with gasoline, transmission oils have a much different set of requirements.

There are two separate grading systems for gear oils.

For universal, or automotive, gear oils there are two sets of standards. Those which are destined for use in transmissions are graded according to SAE standards. You might, for instance, see 80W-90 gear oil or 75W-140 gear oils on the shelves.

Similar to motor oils, the numbers are easy to read. The first number of a multi-grade oil, preceding the W, is the performance at 0°C while the second number rates its performance at 100°C. So, a 75W-140 gear oil has similar performance to an SAE 75 gear oil while at 0°C. The single grade oils performance would only be measured at 100°C. Gear oils can get remarkably close to performing almost uniformly across the spectrum, with grading like 75W-85 gear oil being fairly common. This does not mean much to most end consumers, who will simply want to match off with their owner’s manual for the vehicle.

Things are not quite as complicated when looking at industrial gear oils (ISO). They are most often rated with a single grade but it’s on a different curve than those destined for automotive use. ISO grades are internationally agreed upon standards for oils used in industry. ISO 68, for instance, performs at 67.5cSt at 40°C. ISO grades tend to be much easier to read, since they are tied to the centistokes of viscosity of a substance at 40°C. They are not an exact measurement, but they are close.

Other Desirable Qualities in Gear Oils

Just like any other specialized oil, gear oil has some specific requirements outside of being slippery and being able to handle heat and friction. This is true for both industrial purposes and for automotive transmissions. Gear drives come in a wide variety of designs, which means that you will need to match the oil with the particular type of machinery being used.

Adhesion

In open gear designs, adhesion is required. By holding to the metal of the gears, it provides a thin foam which helps prevent metal-on-metal contact. This quality can be negative in most other designs, however, since it tends to induce higher friction and does not offer much cooling.

Low Emulsion Formation

Gear oils, more than almost any other commonly used oil, need to emulsify water to be removed from the gears. This means that oils which easily emulsify with water, as opposed to separating from it, are highly undesirable. This quality is usually maintained through the use of additives. By separating from water, instead of allowing the liquid to emulsify within it, gear oils can rapidly address the problem to keep corrosion and oil oxidation to a minimum. This is much more important for industrial applications than in automotive ones for obvious reasons.

Foam Inhibition

Because of the way that gear drives work, serious foam formation is a very real probability while things are in motion. This means that foam needs to be inhibited through the use of antifoaming agents in order to keep things from getting out of hand. While not as disastrous as in hydraulic operations, foam can still cause a hindrance in gear systems.

Minimal Interactions with Components

While most mineral oils have little to no interaction with ferrous metals, there are a number of parts in any given gearbox which may interact with oils without the right additives. These include rubber gaskets and seals, and a good gear oil should be formulated to minimize interaction with these parts as well.

Thermal Stability

Gear oils need to remain stable under the heat generated by the gearbox. While all gears are going to produce some heat, the requirements for heat resistance vary quite a bit depending on the application. Faster gears tend to heat up more than slower ones, but slower gears are often under higher loads which leads to more pressure and heat so remaining stable is extremely important. An oil which is not stable will degrade faster and create more sludge within a system in a shorter amount of time than one with a higher thermal stability. There are oils available for even the most extreme situations, so the proper choice of lubricants in machinery is just a matter of finding the right oil for the system in question.

Types of Gear Oil

Like most types of specialized oils, gear oils come with a wide variety of different additives which are designed to handle different situations. In many cases, there are also drawbacks to the additives, which means that making sure the correct additive package is used in the right situation is of paramount importance. Oxidation protection keeps the microscopic debris which inevitably separate from the gears from oxidizing within the oil, prolonging the useful lifespan of the gear oil.

Extreme Pressure Gear Oils

Extreme pressure gear oils are designed to withstand heat and pressure to a much higher degree than any other type. This naturally means a lot of additives, and it can prove to be hazardous if you are not careful about what kind of machine they are put in.

Most of these agents are made with a base of chlorine or sulfur, which can prove hazardous for some metals. For instance, the bronze gears often used in worm-drives can have their surface softened by exposure. This means they should only be used when called for by a manufacturer. Other anti-wear additives, such as zinc-based protectants are desirable for applications where metal is easily affected by chlorine or sulfur are present.

Compound Gear Lubricants

By combining a gear oil with fatty oils, the viscosity of the gear oil can be increased. When combined with the right additives, you end up with an oil which is suitable for low speed, high-pressure applications while still providing high lubricity.

Synthetic Gear Oils

Whether it is super low or super high temperatures, synthetic gear oils are the best choice when you are looking at conditions which other oils simply will not function in. They are created in a huge array of viscosities where pressure is high.

Grading of Gear Oils

GL-1 Gear Oil – These oils are designed primarily for low-use manual transmissions. They usually operate under such low-pressure conditions that there are only minimal additives needed. Friction modifiers and extreme pressure additives disqualify an oil from performing in this category.

GL-2 Gear Oil – These gear oils are used for worm-gear type axles and can have additional additives on top of what is allowed in GL-1 oils. They are still not allowed to use extreme pressure additives.

GL-3 Gear Oil – These oils are used for manual transmissions where the characteristics of a GL-1 or GL-2 oil will not suffice but do not require the amount of load that a GL-4 oil can handle. They are usually used for manual transmissions which operate under moderate to severe conditions. They have a light extreme pressure effect.

GL-4 Gear Oil – These oils possess a moderate level of extreme pressure additives and are the most commonly used gear oil in the modern world. The majority of transmissions use this kind of oil.

GL-5 Gear Oil – These oils possess a very high level of extreme pressure additives. They are primarily used with hypoid gears and other extremely loaded systems.

Leave A Comment